Doortek Solutions can offer any additional security or safety accessories to suit your individual needs, below are some examples of options that you may wish to consider.

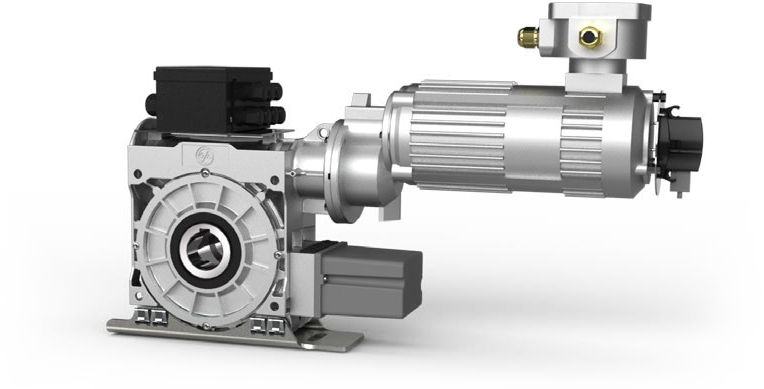

Drive Systems for Hazardous Areas

Under the Dangerous Substances and Explosive Atmosphere Regulations 2002, it is an employer’s responsibility to protect both their staff and the public, from risk to their safety from fire and explosion. Any door that is sited in a potentially hazardous area must comply with the “ATEX” directive, ensuring that any potential sources of ignition are eliminated.

We offer a range of ATEX rated drives for Roller Shutter and Sectional Overhead Doors, both sprung and unsprung, control panels and accessories. The control panels offer the standard open, stop and close operations but can incorporate special functions for specific requirements such as Shootbolt Interlocks or automatic door operation.

- ATEX Certified

- Safedrive® – Safety Brake incorporated

- Range of output speeds and torques

- Horizontal or vertical mounting

- Hollow shaft worm drive gear with directly driven limit switches

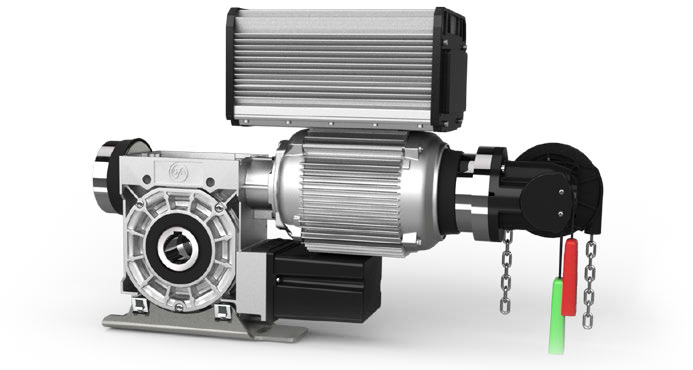

Drive Systems for non-balanced Fast Operating Industrial Doors

The Safedrive® Fi drive system has been specifically developed for powering a range of non-balanced doors where speed, frequency of use and durability are key requirements. All models incorporate the features of the Safedrive® with the added benefits of a built on frequency inverter. All drives are supplied with low level hand chain operation as standard.

On-site wiring costs are greatly reduced as the drive and inverter are pre-assembled and the control is separate, this means the connection between the two can be done with a standard single interconnecting cable and coupled with the standard plug connections. As the drive and frequency inverter are factory assembled prior to delivery, all parameters for the motor voltage, frequency, current, power etc are factory set and tuned for optimum performance and reliability.

- Built on frequency inverter

- Direct setting of actual door speed

- Range of output speeds and torques

- Horizontal or vertical mounting

- Low level hand chain operation as standard

- Plug-connected control equipment

- Safety Brake incorporated

- Certified to BS EN 12453:2001-02

The Safedrive® Fi drive system allows actual opening and closing speeds to be set by entering the required rpm. This is in contrast to the conventional method of calculating the required supply frequency in order to achieve the desired door speed. It is equally simple to set the acceleration and deceleration parameters and the drive limit positions can be set from floor level. The speed change pre-limits and over travel limits are set automatically, therefore on-site commissioning time is greatly reduced compared to separate inverter packages.

Wireless Safety Edge for Industrial and Commercial Applications

The Wireless Safety Edge uses a bi-directional radio connection to replace the conventional spiral cable between a door’s safety edge and control panel. It comes into its own on high usage/high speed doors, where wear and tear can cause spiral cables to fail, resulting in repair costs.

The Wireless Safety Edge is also ideal in public places such as car parks and on the high street where spiral cables could be vandalised, preventing entry shutters, grilles or gates from working. The radio system allows very tall doors ( up to 10m) to be automated when a spiral cable would not stretch far enough.

- 2.4 GHz bi-directional radio communication

- Long battery life

- Safety Category 2 BS EN 13849- 1

- Automatically adjusts the operating frequency during set-up to prevent cross coupling of safety edges on adjacent doors

- Low battery warning and monitoring

Motion & Presence Sensors

Motion Sensor for opening of all Industrial Doors

Radar Technology enables accurate, reliable and targeted opening.

- Opens the door when a vehicle or pedestrian moves in the

detection field - The most suitable technology for opening in industrial environment

- Covers a zone of 4m x 5m (at 5m mounting height)

- Adjustable radar field size

- High immunity to rain and snow

- Unidirectional (the door only opens when the vehicle or pedestrian moves towards it)

- Possibility to detect vehicles only

- Possibility to reject parallel traffic of vehicles

- Can be installed up to 7 meters (depending on size and nature of target)

Presence Sensor for Industrial Doors

Infrared Technology for Increased Protection in front of the Door.

- Offers more protection and convenience to vehicles & pedestrians

- The door will not close as long as a vehicle or pedestrian is in the detection zone

- Increases the protection of the door by reducing collision risk

- Can open the door when a vehicle or pedestrian enters the detection zone and keeps the door open until the vehicle or pedestrian leaves the infrared field

- Possibility to perform like induction loop systems

- Covers a zone of 3m x 3m with 40 spots (at 5m mounting height)

- Adjustable infrared field (9 different possibilities)

Motion and Presence Sensor for Industrial Doors

Dual Technology for Increased Convenience and Protection.

- Motion detection through Radar Technology

- Presence detection through Infrared Technology

- Designed for Industrial environments

- Unaffected by door vibrations and environmental disturbances

- Can be installed up to 6 meters (depending on size and nature of target)

Available Downloads

Other Roller Shutter Doors